Dr. Sung Mook Choi and his research team at the Korea Institute of Materials Science have made a groundbreaking achievement in the field of anion exchange membrane water electrolysis. Their one-step electrode fabrication process eliminates the need for multiple complex steps involved in traditional methods, reducing the process by 60%. This remarkable advancement allows for the direct production of electrodes from raw materials to a mass-producible level, revolutionizing the way electrodes are manufactured for water electrolysis systems.

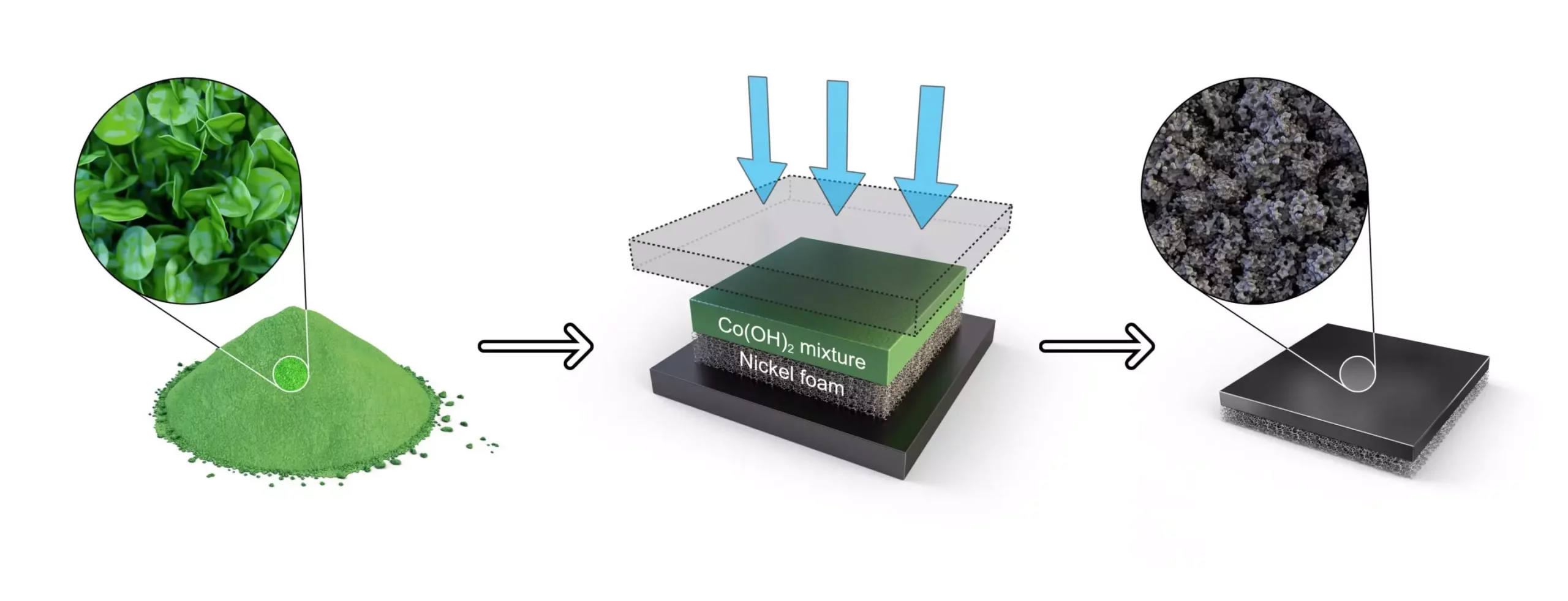

Through careful control of cobalt hydroxide slurry conditions, temperature, and pressure during the hot-pressing process, the research team was able to create a catalyst layer composed of uniform oxide particles, each measuring 10 nanometers in size. This level of precision resulted in a highly uniform catalyst layer that significantly improved the efficiency of hydrogen production and the durability of the electrodes during continuous operation. The developed electrode was successfully integrated into a membrane electrode assembly, showcasing both stability and high performance in a commercial-scale water electrolysis cell.

The potential impact of this technology on the green hydrogen production industry is staggering. With expectations for production to reach 11 million tons and 69 gigawatts of capacity by 2030, the development of a megawatt-level anion exchange membrane water electrolysis system by 2024 in Korea signals a significant step towards commercialization. The current technology level in Korea stands at 70-80% of world-class standards, highlighting the need for continued investment and localization of the technology. By securing the source technology for mass-produced electrode manufacturing, Korea aims to not only dominate the domestic market but also establish a global edge in water electrolysis technologies.

Dr. Sung Mook Choi, the principal researcher behind this innovative electrode fabrication process, emphasized the importance of addressing key challenges related to the commercialization of anion exchange membrane water electrolysis. With a focus on reliability and efficiency, the research team has paved the way for a more sustainable and cost-effective method of producing hydrogen through water electrolysis. As the industry continues to evolve and grow, the development of this groundbreaking technology will play a crucial role in shaping the future of green hydrogen production on a global scale.

Leave a Reply