Small electric motors play a vital role in our daily lives, powering an impressive array of devices—from home appliances to intricate automotive systems. Though each motor operates with minimal energy output, their cumulative energy consumption can be significant, providing ample opportunities for enhanced efficiency and sustainability. The recent strides made by researchers at Graz University of Technology (TU Graz) in the development of brushless drives are a testament to how innovation can dramatically influence these unassuming workhorses of modern technology.

Under the leadership of Annette Mütze, the research team has focused on a multifaceted approach to improving the performance and efficiency of these motors. Notably, the innovations include advanced design strategies and revised control technologies, contributing to quieter, lighter, and more energy-efficient systems. Mütze’s group has particularly emphasized the overhaul of various existing components, which not only minimizes energy consumption during operation but also enhances durability. By addressing these technical challenges, they have created solutions that are both effective and economically viable.

One of the primary issues faced by smaller electric motors is “cogging torque,” a phenomenon that causes jerky movements and unwanted noise during operation. Mütze’s team approached this challenge by implementing skewing and slotting techniques in the motor design, which effectively dampened cogging without incurring additional costs. This significant alteration transforms how the motor engages and moves, resulting in a notable 70% reduction in noise levels. Such advancements are crucial, especially in settings where a quiet operation is imperative, such as residential areas or medical environments.

A pivotal aspect of enhancing efficiency lies in the method used to regulate current flow. Traditionally, pulse width modulation (PWM) is employed, which is effective but often energy-intensive due to the numerous switching operations involved. Mütze’s innovation simplifies this by employing a streamlined switch-on, switch-off approach that operates only once per desired rectangular pattern of current flow. This clever adjustment not only minimizes additional energy consumption from switching losses but also optimizes performance, especially at lower currents, where conventional methods may falter.

As energy efficiency improves, so do production costs. The reduction in switching operations inherently means that the design can utilize half the number of capacitors compared to their PWM counterparts, offering further financial benefits in manufacturing. This cost-effectiveness is essential as industries seek to balance performance with budgetary constraints. By prioritizing such innovations, Mütze and her team have positioned their designs not only as competitive in functionality but also financially appealing.

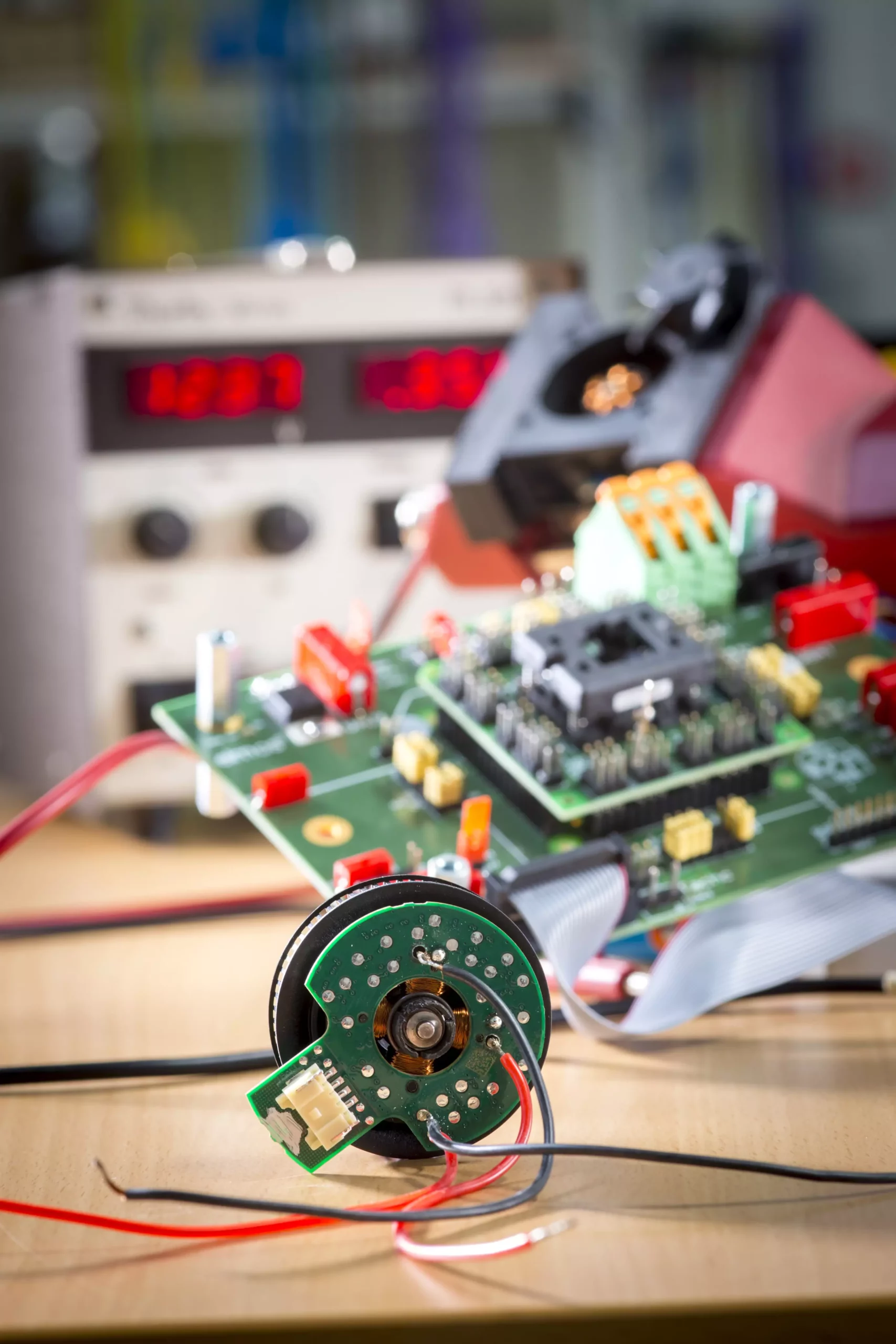

Additionally, the introduction of printed circuit board (PCB) motors marked a significant leap in manufacturing techniques. Creating motor windings as PCB elements allows for high levels of automation, streamlining the production process and reducing labor costs. Furthermore, the incorporation of 3D-printed ferrite cores enhances the efficiency of magnetic flux guidance within these motors. By utilizing more cost-effective ferrite magnets, the overall economics of the motor production process become favorable, encouraging wider adoption of these innovative technologies across various sectors.

The ongoing advancements in brushless electric motors underscore a critical movement towards more sustainable technologies. As researchers like Mütze and her team continuously innovate to enhance efficiency, reduce noise, and cut costs, the implications for industries—from automotive to consumer electronics—are profound. By leveraging creative engineering solutions and embracing new manufacturing methodologies, the potential for energy savings grows exponentially. As we look to the future, these developments signify not only a leap in technology but also a commitment to creating a more sustainable world.

Leave a Reply