The increasing demand for rare-earth elements (REEs) is becoming a pivotal issue as industries, particularly those focusing on renewable energy and electric vehicles, continue to expand. REEs, which include vital components like neodymium (Nd) and dysprosium (Dy), are crucial for producing high-performance magnets utilized in technologies that promise a cleaner, more sustainable future. Yet, the extraction of these elements often leads to significant ecological impact, raising concerns over environmental degradation and resource sustainability. As the world shifts towards carbon neutrality, innovative recycling methods must be developed to effectively reclaim these valuable materials from end-of-life products.

Recent advancements from researchers at Kyoto University herald a new era in the recycling of REEs. Led by Professor Toshiyuki Nohira from the Institute of Advanced Energy, the team has introduced the selective extraction–evaporation–electrolysis (SEEE) process, which promises to offer an efficient solution to recycling magnets that contain these critical elements. What sets the SEEE process apart is its capacity for higher recovery rates and purities compared to traditional methods. With the pressing environmental issues attached to mining operations and their associated carbon footprint, this innovative recycling technique could be a game-changer.

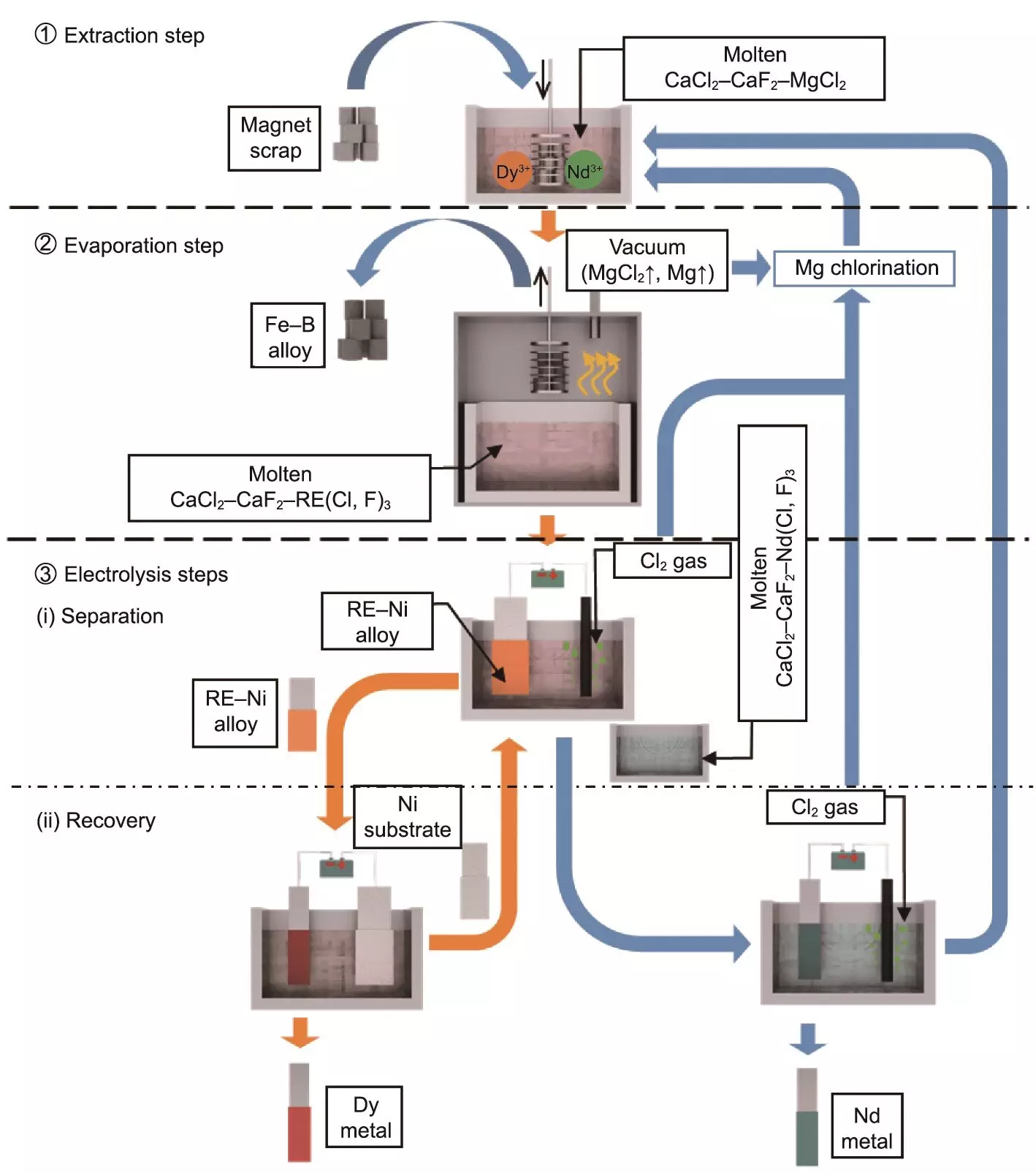

The SEEE process is ingeniously designed with three integral stages that enhance both efficiency and sustainability.

1. **Selective Extraction**: This initial phase utilizes a molten salt mixture—specifically calcium chloride (CaCl2) and magnesium chloride (MgCl2)—to extract REEs from discarded magnet components. Adding calcium fluoride (CaF2) plays a vital role by preventing evaporation losses and ensuring that extraction efficiency is maximized.

2. **Selective Evaporation**: In the second stage, the process focuses on purifying the extracted REEs. Any lingering extraction agents and byproducts are eliminated, thereby concentrating the valuable elements of interest.

3. **Selective Electrolysis**: Finally, the extracted materials undergo an electrochemical process that separates Nd and Dy based on their unique formation potentials. This final step allows for the retrieval of these metals at high purity, which is essential for their subsequent applications.

The SEEE process showcases remarkable recovery rates—achieving 96% for Nd and 91% for Dy—with both elements surpassing 90% purity, a feat that significantly outstrips conventional recycling methods. This efficiency is not only indicative of advanced engineering but also demonstrates a committed approach towards minimizing waste and maximizing resource utility.

Implications for Industrial Applications

The ramifications of this research extend far beyond the recycling of Nd magnets. As the demand for electric vehicles and renewable technologies surges, the need for efficient recycling and reclaiming of REEs is paramount. The SEEE process could diminish reliance on newly mined materials, which comes with a hefty environmental price. Furthermore, the researchers propose that this methodology could also be adapted to reprocess nuclear fuels, thereby broadening its impact across various sectors.

While the initial findings from the SEEE process are promising, it is essential to underscore the need for further technical investigations. Integrating this process into industrial applications is a complex task that may require additional refinement and testing to ensure its commercial viability. Nonetheless, early results provide optimism for its potential contribution to enhancing material recycling practices.

In a world striving for sustainability, innovations like the SEEE process from Kyoto University could prove pivotal in addressing the complexities of REE recycling. This breakthrough not only represents a stride towards responsible management of resources but also aligns with global objectives to mitigate environmental harm while promoting green technology development. As we continue to embrace electric vehicles and renewable energy sources, the significance of efficient recycling solutions becomes more apparent. By investing in advanced research and pushing the boundaries of material recovery, we take critical steps towards ensuring that our resources are managed responsibly, thus paving the way for a sustainable future.

Leave a Reply