The search for sustainable energy solutions has ignited an expanding interest in alternative battery technologies, particularly sodium-ion batteries. Unlike their widely utilized lithium-ion counterparts, sodium-ion batteries utilize sodium—a mineral abundant and easily accessible on our planet. Sodium’s favorable abundance, over a thousand times that of lithium, positions it as a more sustainable choice for energy storage. The ongoing attraction towards sodium-ion batteries is further bolstered by their enhanced electrochemical stability. This characteristic not only facilitates faster charging and discharging cycles but also ensures competence under lower temperatures—key for various applications, especially in electric vehicles and renewable energy systems.

However, sodium-ion batteries face inherent challenges that continue to impede their widespread adoption. One of the primary hurdles is their comparatively lower energy density and lifespan than lithium-ion batteries. A significant aspect contributing to these drawbacks is the complexity involved in synthesizing hard carbon anodes, which are essential due to the larger ionic radius of sodium as opposed to lithium. The unique properties of hard carbon make it a suitable material, but the manufacturing process is sophisticated and resource-intensive.

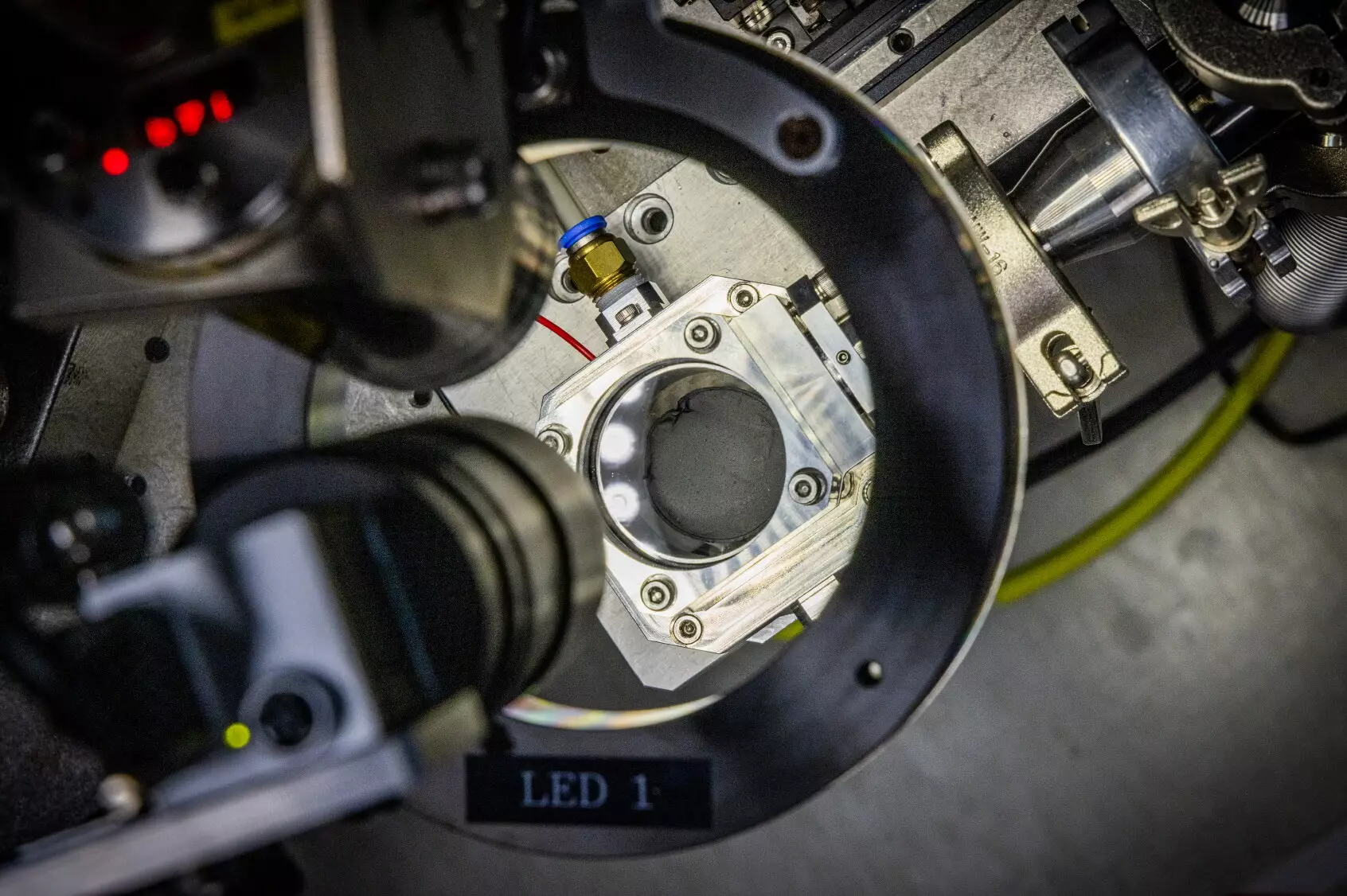

A groundbreaking approach has emerged from a dedicated research team led by Dr. Daeho Kim and Dr. Jong Hwan Park at the Korea Electrotechnology Research Institute (KERI). Their innovative research hinges on a process that employs microwave induction heating to expedite the preparation of hard carbon anodes in an unprecedented 30 seconds. This methodology significantly addresses the energy inefficiencies and costs associated with traditional carbonization processes, where hydrocarbon materials are typically heated in an oxygen-free environment at extremely high temperatures exceeding 1,000°C for extended periods.

Traditionally, preparing hard carbon from precursor materials is laborious and economically taxing. KERI’s new technology eliminates this burden by utilizing microwave technology commonly found in households, thereby making the process not only faster but also more economically viable.

A key factor in the advancement of this technology is the team’s utilization of a multiphysics simulation technique. This advanced approach allowed the researchers to meticulously dissect the complex interactions of electromagnetic fields with nanomaterials during the microwave heating process. The simulations provided crucial insights, enabling the team to design a novel process tailored for the efficient preparation of sodium-ion battery anodes.

The research team’s collaborative efforts also underscore the value of academia-industry partnerships. Co-first authors, student researchers Geongbeom Ryoo and Jiwon Shin, contributed significantly to this groundbreaking study, which exemplifies how collaborative research environments can propel innovation in critical technology sectors.

The implications of KERI’s discovery reach far beyond the realm of sodium-ion batteries. Dr. Kim articulates the promising possibilities of the microwave induction heating technology for various applications, including all-solid-state batteries that necessitate specialized high-temperature sintering processes. The research team’s advancements pave the way for continuous mass production of hard carbon films on a large scale.

As commercial interest grows, KERI has already secured a domestic patent for this revolutionary technology and anticipates fruitful partnerships with energy storage companies eager to capitalize on these advancements. Given the increasing scrutiny on battery safety, particularly post-incident concerns surrounding electric vehicle fires, the demand for safer alternative solutions such as sodium-ion batteries is poised to rise significantly.

The strides made by Dr. Kim and Dr. Park’s research team signify a pivotal turning point in the energy storage landscape. By effectively addressing the challenges surrounding sodium-ion battery production, they not only enhance the feasibility of these batteries but also contribute to the broader movement towards sustainable and efficient energy solutions. As concerns over environmental impact and safety continue to dominate discussions on battery technology, innovations such as this one are crucial, illuminating the path towards realizing the full potential of sodium-ion batteries and, by extension, our transition to a sustainable future.

Leave a Reply