Recent advancements in engineering research have brought to light a transformative study focusing on ultra-high-performance concrete (UHPC) confined by fiber-reinforced polymers (FRP). Spearheaded by a team from Huazhong University of Science and Technology and Southern University of Science and Technology, this study addresses long-standing challenges in understanding the compressive behavior of UHPC, thereby offering a novel analysis-oriented stress-strain model. This breakthrough could significantly alter the landscape of structural engineering, enhancing the resilience and efficiency of modern construction projects.

UHPC is celebrated for its exceptional properties, including remarkable strength and durability, making it a popular choice in contemporary infrastructure projects. However, engineers have faced hurdles when it comes to evaluating its performance under the influence of FRP. Traditional stress-strain models, effective for normal-strength concrete (NSC), have failed to adequately represent the complexities of UHPC behavior. This study exposes the limitations of these conventional frameworks, which often rely on a general assumption of stress-path independency that does not translate well into the context of UHPC.

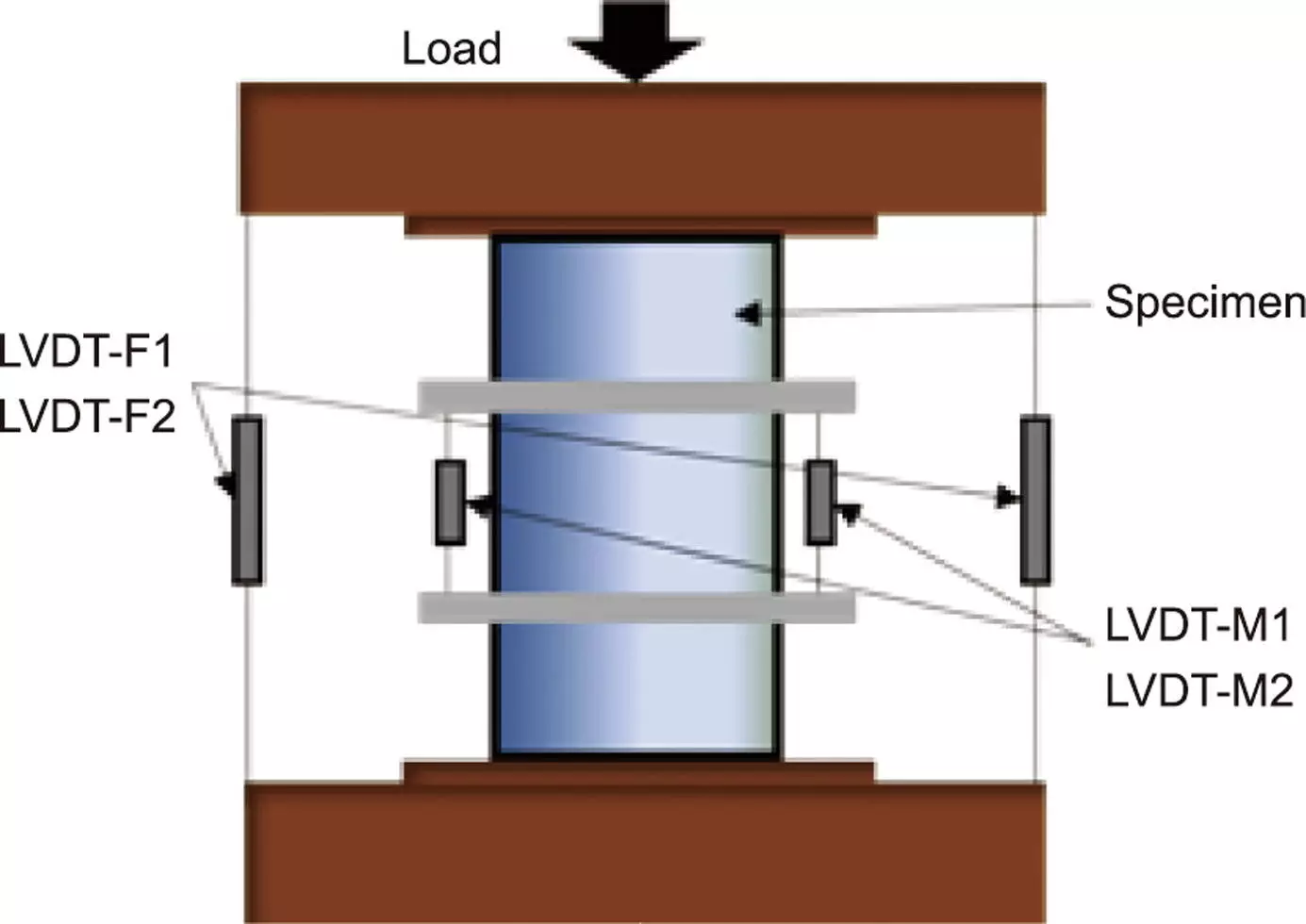

The research team set out to unravel the intricacies of UHPC’s compressive response when subjected to FRP confinement. They conducted extensive experiments that unveiled the inadequacy of prior models in accounting for non-uniform lateral expansion resulting from the development of significant diagonal cracks in UHPC. This discovery prompted the researchers to reassess their understanding of confining pressures and the overall behavior of the material under stress.

A pivotal advancement in this study was the recognition that the stress-path independency assumption does not hold for UHPC. This acknowledgment led the team to innovate by proposing a new model that integrates stress-path dependency into the analysis of FRP-confined UHPC. By adjusting the confining pressure calculations and introducing a new equation to consider the gap in confining pressure, the researchers have created a framework that more accurately captures the material’s behavior. This nuanced approach empowers engineers with a more precise tool for analysis and design.

To establish the reliability of their newly devised model, the researchers subjected it to rigorous testing against a comprehensive database of prior experimental results. The outcome demonstrated that their model not only predicts the stress-strain behavior accurately but also offers superior predictive capabilities compared to existing models. This robust validation is a testament to the model’s transformative potential in the field of structural engineering.

The implications of this research extend far beyond the immediate analysis of UHPC behavior. By providing engineers with a more reliable model, the study enhances the safety and performance of structures utilizing UHPC. The accurate prediction of FRP-confined UHPC behavior paves the way for enhanced structural designs, potentially leading to innovations that prioritize efficiency and longevity in construction processes.

Moreover, the findings of this study could inspire additional research avenues, encouraging further investigations into the behavior of high-performance concrete systems under varying conditions. As the construction industry embraces more advanced materials and technologies, the insights garnered from this research will be crucial in fostering growth and sustainability.

The innovative stress-strain model introduced in this study signifies a watershed moment in the realm of concrete technology. By addressing the shortcomings of existing models and providing an analysis-oriented approach, this research not only enhances the design principles of UHPC structures but also enriches the knowledge landscape within the field of structural engineering. As researchers and engineers continue to build upon these findings, the future of high-performance concrete applications looks promising, offering unprecedented opportunities for safer and more efficient construction.

Leave a Reply