The quest for viable materials in nuclear fusion technologies has long posed significant challenges to researchers. A groundbreaking study spearheaded by the Oak Ridge National Laboratory (ORNL) has unveiled a noteworthy development: an artificial intelligence (AI) model designed to identify innovative alloys for use in fusion reactors. This research, which has been in the making for several years, promises to revolutionize the way materials are selected and developed for high-stakes applications within nuclear facilities. By leveraging advanced AI techniques, this project has the potential to expedite the discovery of alloys that are not only effective at high temperatures but also robust enough to withstand the extreme environments of a fusion reactor.

Historically, the predominant choice for alloys in fusion applications has been tungsten, known for its high resistance to temperature extremes. Though tungsten effectively serves its purpose, inconsistencies in shielding performance have spurred scientists to explore alternative materials. In a move toward innovation, the materials science community is now investigating the possibility of utilizing completely novel metallurgical combinations. This shift acknowledges the limitations of traditional approaches and highlights the need for disruptive advancements in material design—an area where AI could serve as a catalyst.

Massimiliano Lupo Pasini, an ORNL AI data scientist, emphasizes the need for alloys that exhibit superior structural mechanical properties at elevated temperatures. “These alloys are essential for achieving exceptional performance under extreme conditions,” he commented. By utilizing AI, researchers can circumvent the exhaustive trial-and-error processes typically associated with materials discovery, allowing them to swiftly identify feasible alloy candidates from an extensive array of metallic combinations.

The creation of this AI model was not a solo endeavor; it involved collaborative efforts from a team of skilled scientists, including German Samolyuk, Jong Youl Choi, Markus Eisenbach, Junqi Yin, and Ying Yang. Together, they generated the necessary data to inform the model, focusing on identifying three elemental candidates to explore further. Their combined expertise spans several domains within ORNL, weaving a network of interdisciplinary knowledge crucial for the success of the initiative.

However, the process of data generation itself was labor-intensive. The team relied heavily on the computational might of supercomputers, namely Perlmutter and Summit, to perform sophisticated calculations that would otherwise be impractical. Lupo Pasini notes that “generating the data took over a year,” underscoring the challenges inherent in high-performance computational tasks. The results of their work have been documented in the journal Scientific Data, representing a significant milestone in the field of materials science and AI integration.

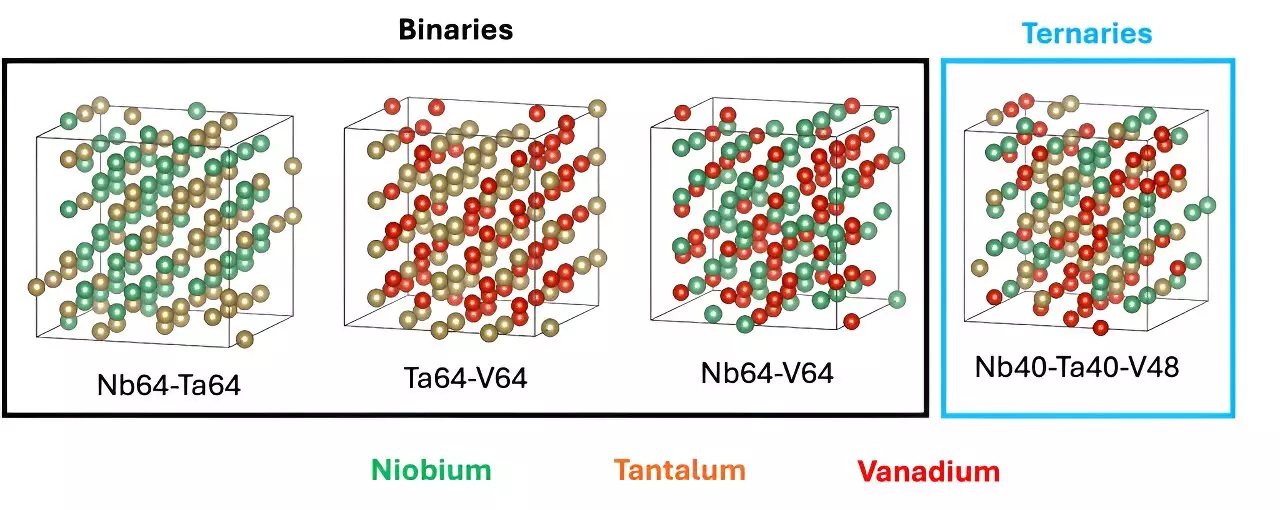

Despite the promising results, this AI-generated database merely marks the beginning phase of a larger project. The next steps involve further research aimed at refining AI models for materials discovery. The ultimate goal is to enable the design of refractory high-entropy alloys by analyzing combinations of six distinct elements. This complex yet crucial step underscores the importance of having detailed data to support the training of ML models, as traditional quantum mechanical calculations can be resource-intensive on current supercomputers.

The ambitious scope of this project raises important questions about the future of materials research. Will the integration of AI transform traditional methodologies in ways that accelerate technological advancements? Lupo Pasini appears optimistic, asserting that the model’s capabilities can guide material scientists in optimizing the composition of alloys. By quantifying the relative percentages of varying elements needed to form effective combinations, the team is poised to facilitate groundbreaking advancements in the realm of nuclear fusion technology.

As the field of nuclear fusion continues to evolve, the introduction of AI-driven approaches to alloy identification signifies a pivotal shift in research methodologies. By effectively harnessing the power of machine learning, scientists at ORNL are paving the way for breakthroughs that could redefine the standards of material performance in extreme conditions. As this research unfolds, it holds the promise of not just enhancing fusion technology but also reshaping the future of energy production itself. The interplay of AI and materials science stands as a testament to human ingenuity, pushing the boundaries of what is possible in the pursuit of sustainable and effective fusion energy solutions.

Leave a Reply